Canteliver Slide Gate Theory

The term, cantilever slide gate, may refer to any number of gates, from ornamental picket styles to functional chain link styles, from those that require cantilever rollers to those requiring gate tracks and trolleys. All cantilever slide gates will share certain characteristcs which differentiate themselves from other types of slide gates. Cantilever slide gates are unique from other types of slide gates in their construction, hardware choices, and design.

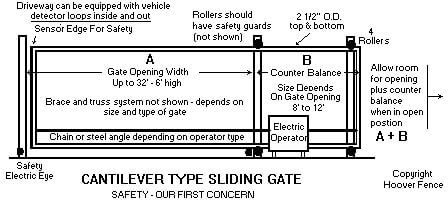

Cantilever slide gates are built larger than the gate opening they are designed to close, often as much as 50% larger than their respective openings. The idea here is to hang the gate on two or more mounting posts and have the gate suspend off these mounting posts into the gate opening to close. In general, no part of the gate comes in contact with the ground directly, or indirectly with any type of wheel. Instead, these slide gates ‘cantilever’ to close the opening. Cantilever construction allows for overhanging structures without external bracing. It is key that cantilever gate frame be constructed properly to help withstand the forces of gravity and wind. Intricate diagonal bracing and trusses are usually strategically welded in place to help prevent gate sag.

Advantages to cantilever slide gates over other styles are numerous. Since no part of the gate comes in contact directly or indirectly with the ground, cantilever slide gates are easy to automate with gate operators. Gates can often very easily be installed perfectly level. Proper design, fabrication, and installation of a cantilever slide gate will reduce friction during operation and prolong the life of a gate operator. Gate hardware systems from a quality fence supply source will provide smooth operation and low maintenance. A cantilever slide gate features the ability to slide along the fence line without requiring any lateral space as swing type gates demand.

Other types of slide gate systems may have a leading edge wheel installed on the latch side of the gate. These leading edge type wheels either roll directly on the ground, or on a track installed across the driveway or gate opening. Care must be taken to assure the gate opening or driveway is kept perfectly clear of debris or wheels will meet obstructions. Gates which slide on a track imbedded on the ground are often referred to as V-Track gates. Essentially a piece of inverted angle iron is bolted down to concrete and a special v-groove wheel rides it. Gates which have a rubber or pneumatic wheel to roll over the ground are simply Rolling Gates. V-Track gates are popular in southern regions where snow and ice are rare. V-Track gates are often automated with gate operators. Rolling gates on the other hand are popular in northern and southern regions. Both these styles can be appealing as they often will not require a counterbalance which can be as large as 50% more than the gate opening. Automating a slide gate requires the gate slide perfectly in both directions and be installed level. Although this is often easiest to accomplish by installing a cantilever gate, v-track gates and rolling gates can also carefully be automated. Again, automating a slide gate requires the gate slide perfectly in both directions! Possible obstructions to leading edge wheels such as snow, ice, and other debris will cause gate operator failure. Gates which do not stay on their tracks can be extremely dangerous when opened and closed manually, and especially with a gate opener.